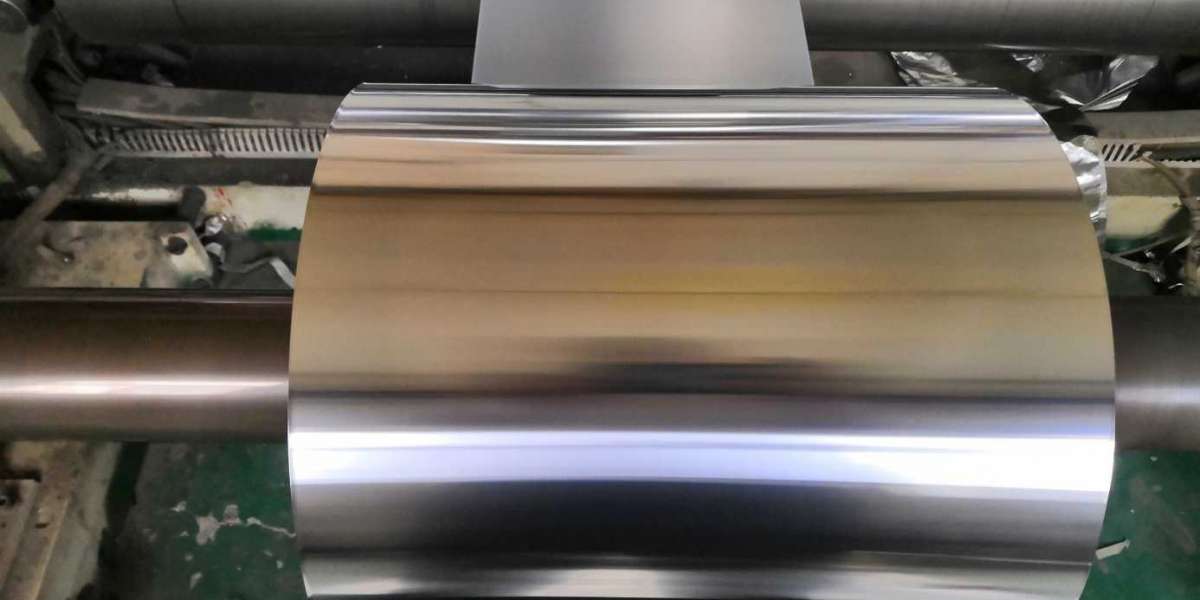

8011 is a regular alloy of aluminum sheet for bottle caps. With tempers of h14 and h16, 8011 sheets are made into ropp caps and closures for bottles of medicine, spirit, wine, juice, milk powder, tea and so forth. The sheets may be received with the aid of either bloodless rolling or warm rolling in large scales, boasting easy technique, 0 pollution, excessive recycling charge and smooth further processing.

The thickness of ropp cap aluminium coil sheet we can supply is from zero.15mm to zero.23mm (thickness tolerance 0.005mm). Attributable to its small thickness, the sheet is usually seemed as 8011 aluminum foil in China. But, if it’s too thin, like a 0.1mm aluminium sheet, its mechanical homes could be reduced correspondingly. Sheets of thickness round zero.2mm show an first rate bending belongings, and they're less likely to break beneath the punch press. 8011 aluminium sheet for bottle caps are easy and easy in surface, tremendous in light and moisture insulation, robust in pierce and punch resistance, and sanitary in use. The width of Huawei closure sheets is from 330mm to 1000mm, with a width tolerance of 1mm. Primarily based on exceptional tempers and alloys, the sheets’ tensile power is a hundred and fifty to 165Mpa and elongation over 2%. The floor of the sheets are free from obvious roll marks, black traces, oil spots, ash, scratches or bright strips, and the ear-making fee is managed within three%.

The manner of decorative aluminum sheet for bottle caps is more complex than simple ones. Take 8011 H16 bottle cap cloth technique as an example. It takes a chain of steps to supply certified 8011 H16 bottle cap materials, along with cold rolling-foil rolling annealing thickness, annealing-foil rolling completed product, stretch bending correction, slitting, slicing, painting, drying, a couple of stamping, and anti-counterfeiting markings on the surface. 8011 H16 medical bottle cap fabric and wine cap fabric are still barely specific in the manufacturing process. Because wine cap stretch requirements are higher than drug caps, they're differentiated in terms of annealing.

Search

Popular Posts

-

Как возможно быстро заказать диплом в интернет-магазине

By sonnick84

Как возможно быстро заказать диплом в интернет-магазине

By sonnick84 -

Что готов сейчас предоставить магазин с дипломами?

By sonnick84

Что готов сейчас предоставить магазин с дипломами?

By sonnick84 -

Что требуется из оборудования для изготовления документов?

By sonnick84

Что требуется из оборудования для изготовления документов?

By sonnick84 -

Как можно купить сейчас неотличимый от оригинала диплом в интернете?

By sonnick84

Как можно купить сейчас неотличимый от оригинала диплом в интернете?

By sonnick84 -

How will it be possible to determine the reputation of an online casino now?

By sonnick84

How will it be possible to determine the reputation of an online casino now?

By sonnick84